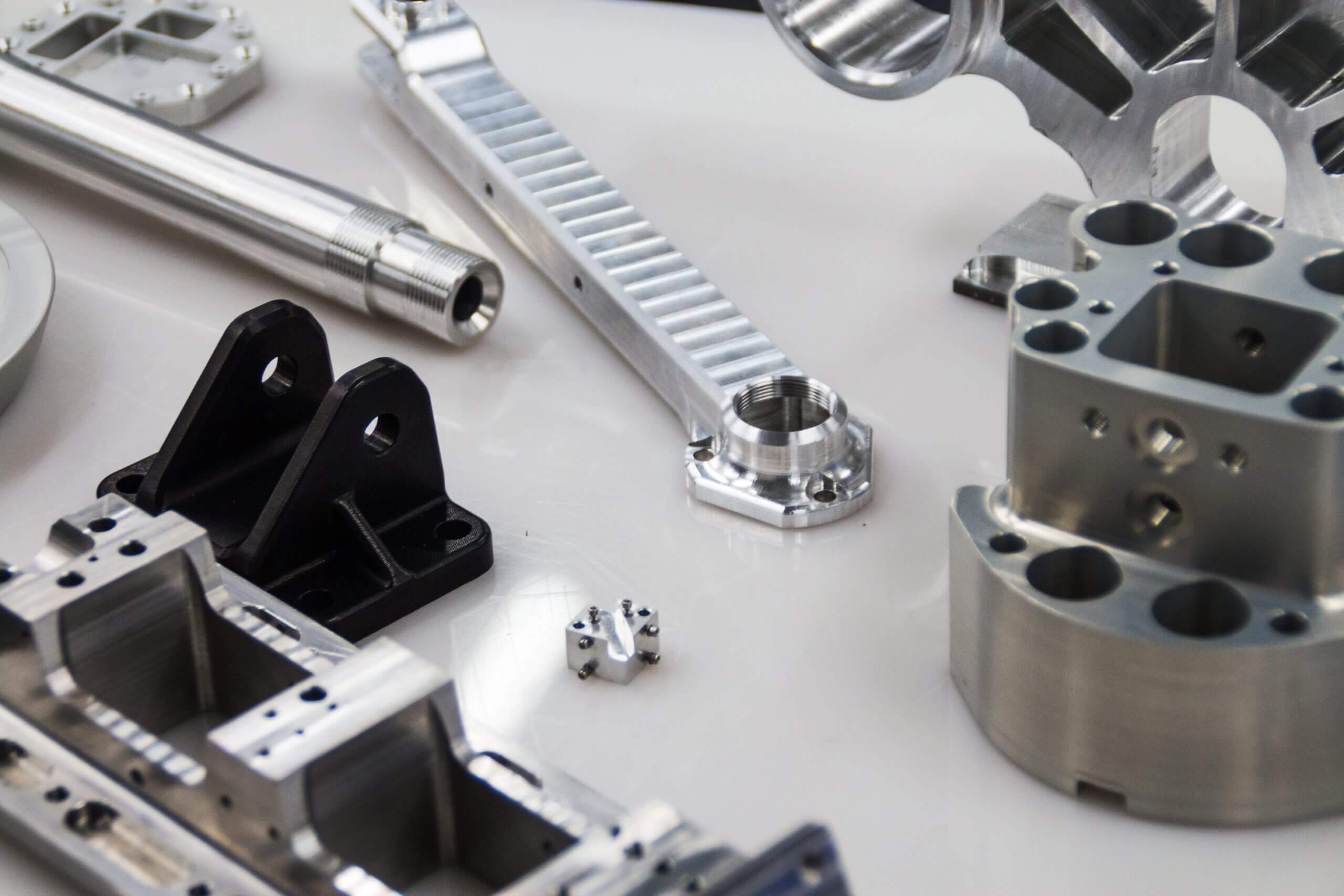

Precision engineering quality is of paramount importance and we have a dedicated Quality Control team.

The Stonehill Engineering philosophy is that of continuous improvement, individuals are encouraged to develop or improve the process they are involved in. Quality procedures are computerised at every stage to ensure compliance with customer needs and quality standards.

We operate a very successful continuous improvement policy across the business in order to achieve objectives including quality, schedule and cost performance. As this is coupled with investment in people, processes and a modern well-maintained plant, we can provide our customers with excellent quality and value.

Our team have over 50 years’ experience in quality and inspection. They continuously check all components during production and a final inspection process is carried out by our accredited company inspectors. Our machinery is always well-maintained and constantly checked by qualified engineers to ensure full performance.

MACHINE TYPE

WORKING AREA

Coordinate Measuring Machine (CMM) QCT Quantum III-L

1000mm x 600mm x 500mm using Inspect 3D pro software

QCS 3D pro measuring software

Mitutoyo surface finish measuring equipment