The Stonehill Engineering team can advise on design, material selection and product enhancement

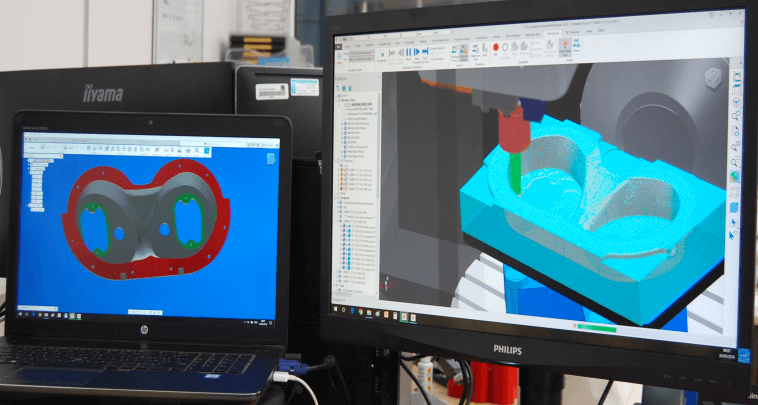

Our skilled in-house design department creates, designs and alters bespoke components for clients. 3D CAD technology, compatible with all the latest process-flow software, is used to compose accurate engineering drawings. These can be developed to produce computer visual models and solid models. The result is a fully bespoke and accurate manufacturing process from start to finish.

Our team can turn an idea into 2D and 3D forms allowing the development of a component into the sample/prototype stage through the various production routes, whether this be machined components, prototype mould tools/mouldings or even on to full production tooling and mouldings which are just a number of our design capabilities.

Close collaboration with the customer at the early stages of product development is essential, when advice can be given on the best design, material selection and product enhancement. This advice reduces the cost of tool sampling, product development time, production costs and along with our policy of investment in new equipment and people, optimises product quality.

Research and development are an integral part of the business; with a high level of skill in the most advanced engineering techniques. Component drawings can be swiftly produced on 3D CAD and developed to produce computer visual models and solid models. Component designs are compatible with all the latest process-flow analysis software. Careful assessment of product design provides cost benefits, assured performance reliability and ensures rapid market entry.

To find out more about our design capabilities, please contact us.

MACHINE TYPE

Alphamcam

Power Mill