Welcome to Stonehill Precision Engineering, specialists with 36 years of experience in producing quality precision-engineered parts for a wide range of markets, including the automotive, defence, rail, transport and scientific sectors.

Stonehill Engineering operates from a purpose-built factory in Huntingdon, Cambridgeshire and has been established for over 36 years. We combine hands-on experience and skills of a traditional engineering business with expert design and project engineers and state-of-the-art equipment.

We work closely with our customers to offer a complete service, including product design, project management, prototyping, 3D modelling, testing and production, ensuring high standards every time.

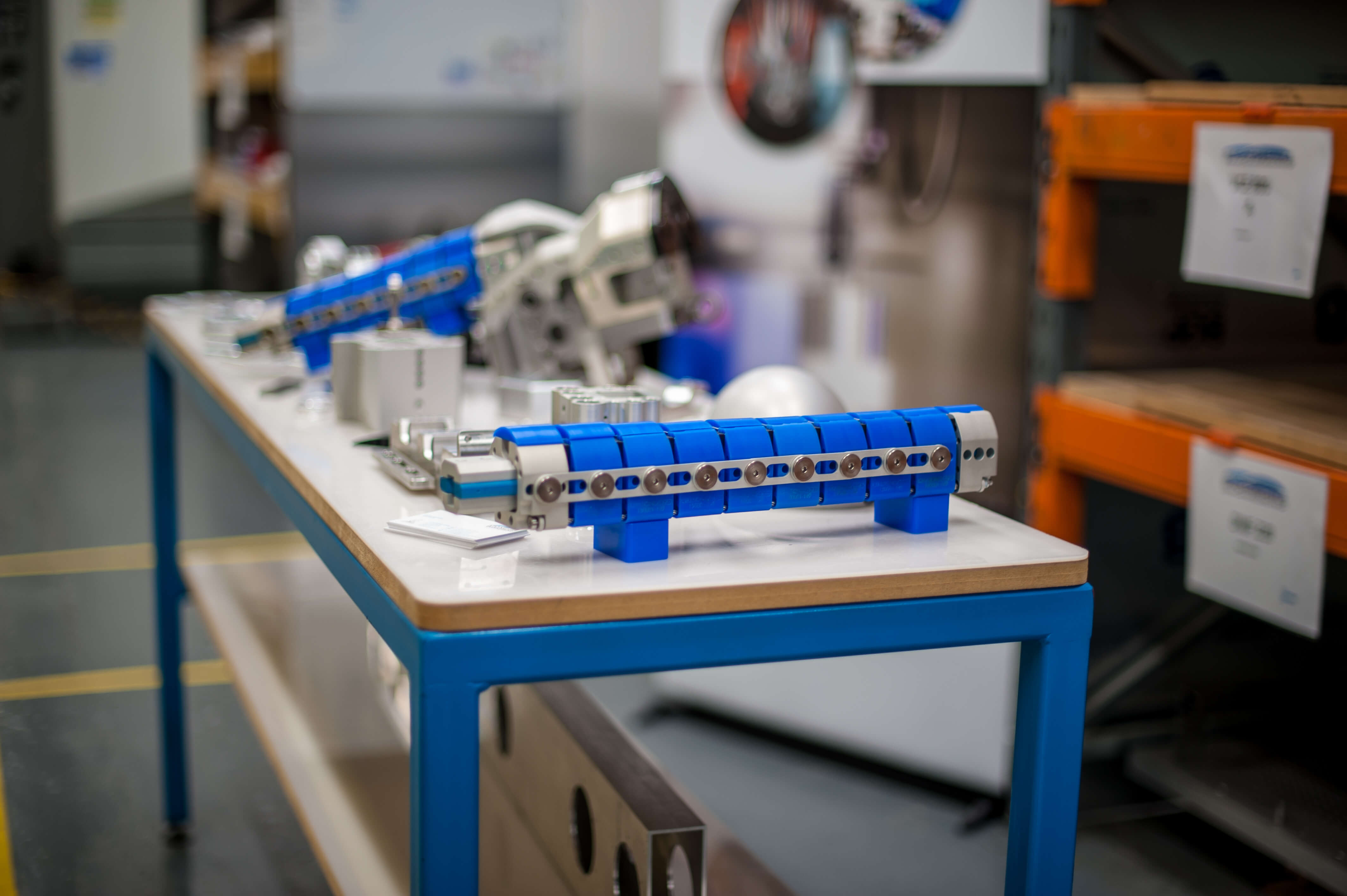

Our experienced team has the flexibility and skills required to produce one-off prototypes or full-batch production using the latest 5-axis equipment for a faster turnaround at a competitive price.

The Stonehill Engineering team often works in partnership with leading industrial designers and major automotive manufacturers and has a proven track record in the timely completion of numerous development projects. These range from complex electro-mechanical devices to passive automotive safety systems.

Visit the Gallery to see examples of precision engineering projects we have completed for our clients including producing tooling, moulds and machined parts for Crash Test Dummies, serial production of knee ligaments for pedestrian safety testing and machining custom parts for motorcycles.